This expression originally meant being sprayed with water; it can also imply being overwhelmed, ruined, or unfairly treated. However, for this instance, it means being the victim of rubber hose failure(s). Get ready for this tale… When I built my modified 1940 Ford coupe in its present form about 10 years ago, I installed a custom built 347 c.i. Ford ohv stroked 302 engine. It was immaculately assembled by Russ Newnes when he was working part time at the Blue Oval in Denver. I finished the build with an MSG throttle body fuel injection system. MSG has now been acquired by Holly, and the throttle body system (somewhat modified) is sold as the Sniper system.

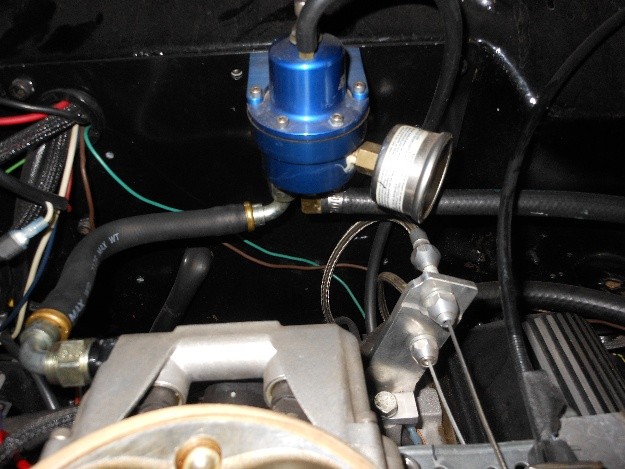

The TB (throttle body) system requires a high pressure fuel pump, pressure regulator, and a return to tank gas line. This required me to do some fancy modification and additions to the old Ford gas line, which was just a metal line going from the gas tank to the mechanical cam shaft driven mechanical pump mounted in time honored fashion on the rear of the engine block. Here is the path piece-by-piece of the added lines.

The TB (throttle body) system requires a high pressure fuel pump, pressure regulator, and a return to tank gas line. This required me to do some fancy modification and additions to the old Ford gas line, which was just a metal line going from the gas tank to the mechanical cam shaft driven mechanical pump mounted in time honored fashion on the rear of the engine block. Here is the path piece-by-piece of the added lines.

- The drain plug was removed from the tank, and a fuel pickup line added, which ran by Hose A to the low pressure filter.

- Hose B then ran from the low pressure fuel filter to the input of the high pressure pump mounted on the rear frame cross member.

- The output of the high pressure pump ran by Hose C to the input of the high pressure fuel filter.

- The output of the high pressure filter required a short jumper Hose D to an added metal line, which runs from the rear of the body to the engine compartment.

- Hose E runs to the fuel input of the TB.

- Hose F runs from the output of the TB to the fuel pressure regulator input.

- Hose G runs from the output of the fuel regulator to the original Ford metal gas line. which becomes the return line to the tank via the fuel filler neck tube.

There you have it – the entire hose picture A,B,C,D,E,F,G, or if you are sophisticated as well as classical, you can instead call them: Alpha, Beta, Gamma, Delta, Zeta, Eta, Theta

I now call them: YOU ROTTEN SONS OF BITCHES

Why am I so vulgar and harsh? I went down to the auto store and bought rubber gas line hose of the correct diameter, cut them to the right length, and used new worm drive hose clamps to fasten then to the proper style fittings for hoses. For years the engine ran great with no problems. That 1940 Ford has been as reliable as mother love. Then one day I noticed a gas drip on the floor of the garage. A was leaking, and the slightest spark would have “Caused a Major Fire Burning the Car and House Down.” (CMFBCHD). A was replaced.

A few months later I noticed a gas drip on the floor of the garage. C was leaking, and the slightest spark would have CMFBCHD.

Charlie Palmer watched me move the Ford out of the garage for the club auction set up, and I noticed a gas drip on the floor of the garage. D was leaking, and the slightest spark would have CMFBCHD. Charlie put in a new line for me.

Earlier this month while getting ready for the rod run to Rosie’s with the hot rod guys, I noticed a gas drip on the floor of the garage. E was leaking, and the slightest spark would have CMFBCHD.

WHAT IS THE PROBLEM?

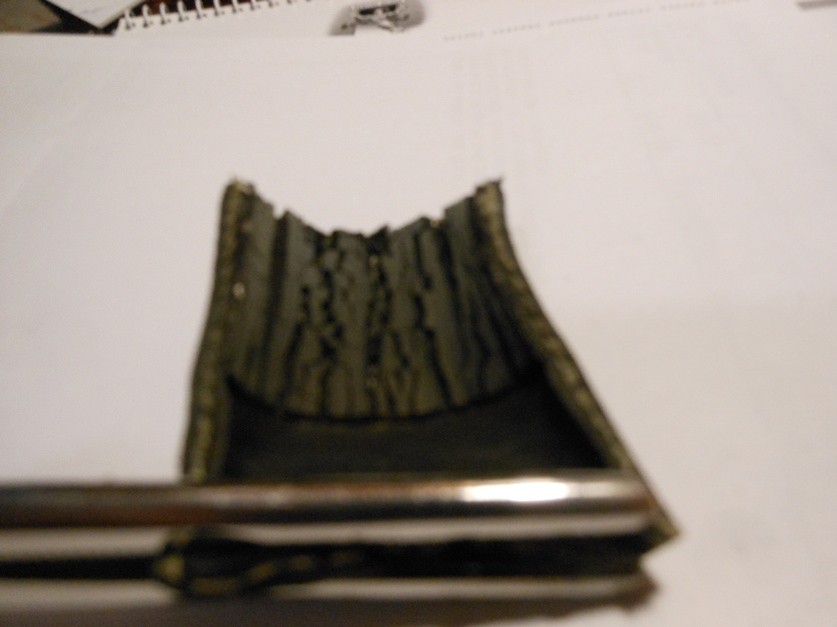

Enough is enough – this has got to stop! It is way past time that I should put on my engineer hat and do some trouble shooting as there is obviously a material problem. Hoses designed for automotive fuel use should never fail and leak! Cutting a failed section of hose open, this is what I found:

Enough is enough – this has got to stop! It is way past time that I should put on my engineer hat and do some trouble shooting as there is obviously a material problem. Hoses designed for automotive fuel use should never fail and leak! Cutting a failed section of hose open, this is what I found:

The liner of the hose in contact with the fitting was fine. The inside liner of the hose in contact with the gas was severely eaten away and obviously the cause of the leak. Our beloved subsidized alcohol corn gas eats the nitrile lining of this hose. Like a malignant cancer, the alcohol slowly eats the lining until it finally fails, perhaps years after it was installed, and a leak happens. I was lucky that I detected all my leaks in my garage where they could be stopped by replacing the hoses. I hate to think what would have happened on the way back from Rosie’s Dinner if the line let go on I-25 going 75 mph.

So what is a guy to do? An obvious lesson is to install all metal lines like the manufacturers do. That may not always be feasible, and if you buy the right specification gas line, you can be safe with rubber hose. All quality hose has printing on it, which if researched, tells you exactly for what it can be used. You may see SAE – 30R7. This stands for the Society of Automotive Engineers specification 30R7. You type this into your friendly ChatGPT program and find out:

SAE 30R7 Fuel Hose Overview

- Purpose: Designed for use as fuel lines, PCV (positive crankcase ventilation) connections, emission control lines, and fuel return lines.

- Compatible Fluids: Unleaded gasoline, diesel fuel, ethanol blends (E10, E85), and sour gas.

- Pressure Rating: Typically rated for low-pressure applications (around 50 PSI); not suitable for fuel injection systems or high-pressure lines.

- Temperature Range: Operates between -40°F to 257°F (-40°C to 125°C).

- If you’re working on a vehicle or engine project, SAE 30R7 hoses are a solid choice for low-pressure fuel and vapor lines. Want help picking the right hose for your setup or comparing it to other SAE specs like 30R9 or 100R5?

Therefore, OK for your Holly carburetor, but not for my 1940 Ford with fuel injection.

Another possibility is to go to a specialty hot rod shop like On Track and seek the advice of the staff, which is very knowledgeable about the specs and will sell you the right line for your application. For example Earls fuel line:

Earl’s Vapor Guard fuel lines are a popular choice for handling E85 and other modern fuels due to their multi-layer construction and resistance to permeation.

Here’s a quick overview of what makes them suitable:

Earl’s Vapor Guard Fuel Line Features

- Fuel Compatibility: Approved for E85, ethanol, methanol, gasoline (leaded/unleaded), diesel, biodiesel, and gasohol.

- Construction:

- Primary Barrier Liner: Resists heat and aggressive fuels.

- Vapor Guard Barrier: Thermoplastic layer minimizes fuel vapor escape.

- Reinforcement Braid: Aramid material (in EFI hose) supports high pressure for fuel injection systems.

- Exterior Cover: Withstands heat and abrasion.

- Pressure Rating: Up to 225 PSI.

- Sizes Available: Commonly in 3/8″ diameter, sold by the foot or in bulk lengths.

This is what I now use.

You may have heard about PTFE fuel line, which I used instead of metal line, on my 1962 Pontiac “Bluebird” with the LS3 engine. PTFE (Polytetrafluoroethylene) fuel lines are a popular choice in high-performance and racing applications due to their superior chemical resistance, durability, and ability to handle high pressures and temperatures.

Here’s a quick overview:

Key Features of PTFE Fuel Lines

- Chemical Resistance: PTFE is highly resistant to fuels including gasoline, ethanol (E85), methanol, and other aggressive chemicals.

- High Temperature Tolerance: Can typically withstand temperatures from -70°C to 250°C (-94°F to 480°F).

- Low Permeability: Prevents fuel vapor leaks, making it ideal for emissions-sensitive applications.

- Durability: The inner PTFE liner is often paired with a stainless steel or nylon braided outer layer for added strength and abrasion resistance.

- Applications: Commonly used in fuel injection systems, turbocharger oil lines, transmission coolers, and power steering systems.

Popular Options

- EVIL ENERGY PTFE Fuel Line Kits: Available in various sizes (4AN to 10AN), lengths (10FT to 25FT), and materials (nylon or stainless steel braided). Compatible with E85 and other fuels.

- Aeromotive PTFE Fuel Lines: Feature carbonized liners for conductivity and are designed for street and racing use.

- Vibrant Performance PTFE Hoses: Offer both stainless steel and nylon braided options with excellent flexibility and resistance

It is very expensive, and you must use AN fittings.

So the next time you go to the auto parts store to buy some gas line, be sure to check what is printed on the hose and be sure you buy the right stuff.

Think CMFBCHD!